Six Sigma (Black Belt)

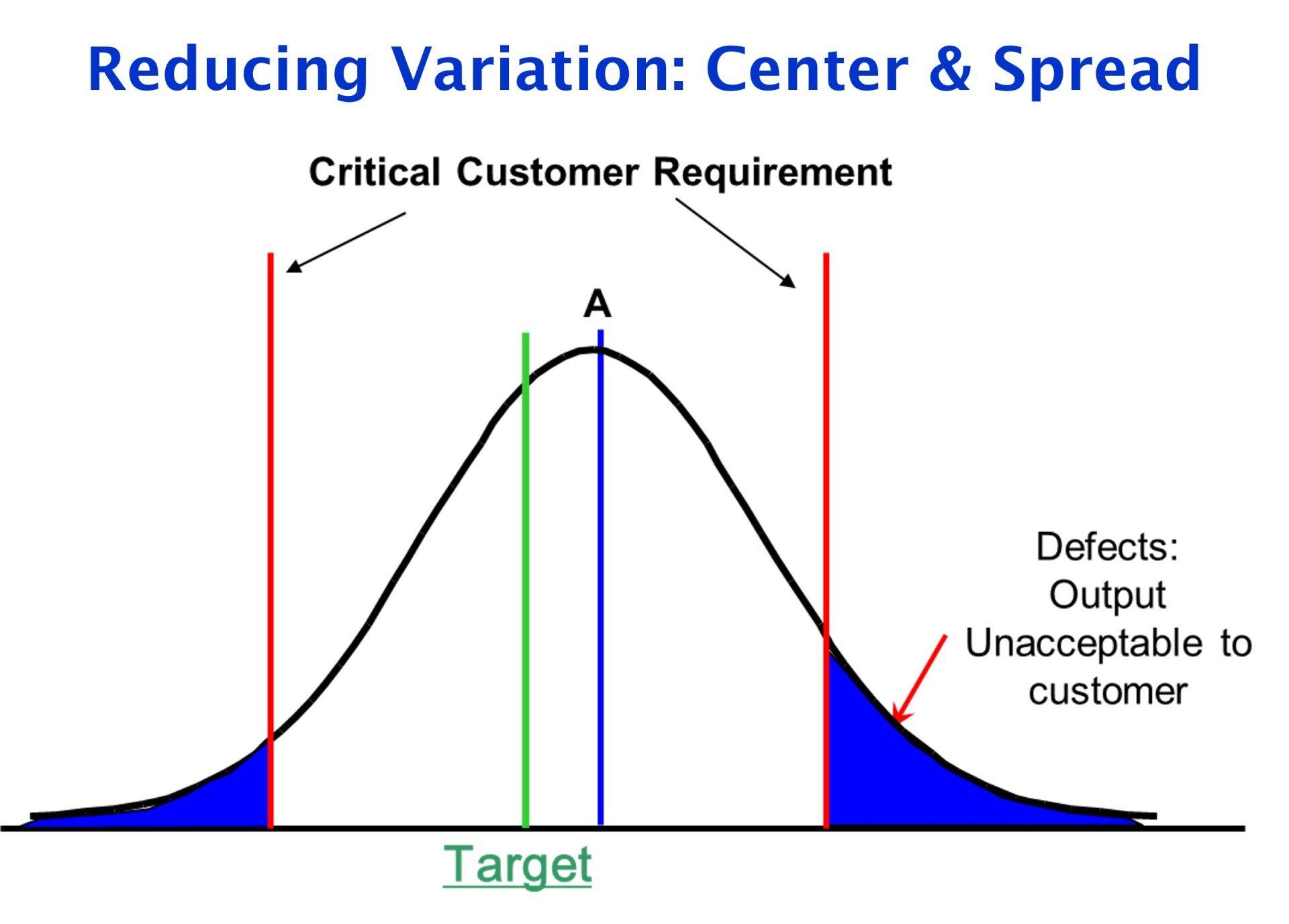

Develop Black Belt knowledge and skills to effectively and efficiently lead teams through the six sigma method. Learn and apply detailed statistical analysis to decrease process defects and variation.

Goal:

To increase your knowledge and skills of the Six Sigma DMAIC (Define, Measure, Analyze, Improve, and Control) process and methods and be able to use it to lead a team through a process variance or defect reduction project.

Benefits:

- Focus on increasing customer satisfaction.

- Improve productivity and financial performance.

- Engage team members in decreasing process variation, reducing defects, improving quality and safety.

- Create predictable and controllable processes.

- Gain processes to follow, techniques and templates to use for collecting and analyzing data to measure the current process; identifying, evaluating, and installing the solutions to measure and control performance; and continually improving.

- One year CI Community of Practice membership.

Agenda:

Training: 96 hours of education and immediate application. Participants bring a scenario to class on which to focus and practice.

Application and Coaching: 4 days of on-site event co-lead. One-on-one coaching until results are achieved.

Certification: Participation in this course and completion of 1 project = Continuous Improvement Six Sigma Black Belt CERTIFICATION.

| Agenda: (96 training hours can be spread over more than 3 weeks) |

|---|

| Training – Week 1 (4 days) |

| 1. The role of a Continual Improvement Champion in leading the method |

| 2. Project selection and how to lead a team through the Six Sigma process |

| 3. DEFINE: Define the problem, goal, and critical customer requirements; calculate Return On Investment |

| 4. MEASURE: Establish process scope and characteristics, map the current process, and establish measurement system and data collection |

| 5. ANALYZE: Calculate and analyze process capability |

| Training – Week 2 (4 days) |

| 1. ANALYZE: Basic and advanced statistical data analysis and identification of root causes, Use of Minitab software |

| Training – Week 3 (4 days) |

| 1. IMPROVE: Define, develop, test, and implement improvements |

| 2. CONTROL: Document, train, go-live, establishing continual improvement system with (control measures and feedback mechanisms) |

| Application with the team (following each training week) |

| • One-on-one coaching to confirm/prepare for initial application |

| • On-site project, with coach as co-lead (real, immediate application and results) |

| Certification (after completion of additional project) |

| • Project documentation review and team survey & CERTIFICATION RECOGNITION! |