Value Engineering and Design For Excellence

Value Engineering and Design for Excellence

Goal:

To develop knowledge and skills of the Value Engineering and Design for Excellence methods and be able to critically analyze the value of every item’s component, decrease item, processing, and operating costs. The team will use the analysis to identify component and assembly design changes that significantly reduces item costs + process times and quality.

Benefits:

- Better designed items.

- Items and processes are performed with less cost, time, and higher quality.

- Reduced operating costs.

- Increased margin and profitability of products.

- Increased pride and ownership of improved products.

- Engage team members in improving the process, product, or service. Increased pride and ownership of improved products.

Agenda:

Training: 40 hours of education and application. Participants bring a scenario to class on which to focus and practice.

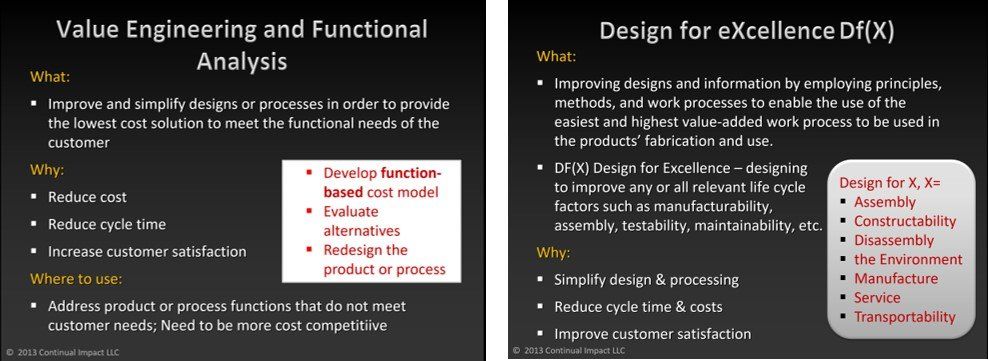

- Leading a team through the Value Engineering process.

- Confirming and Preparing the team.

- Facilitating the process.

- Gathering and analyzing current state data (customer, regulatory, costs and processes (procure, fabricate, assemble, inspect, rework, ship, warranty)).

- Performing the functional analysis.

- Identifying alternative ways to satisfy functions.

- Prioritizing, selecting, testing, and implementing improvements.

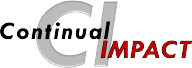

2. Leading a team through the Design for Excellence process.

- Facilitating the process.

- Performing the cost analysis.

- Defining the “x” (construct, assemble, dissemble, environment impact, service, transport, etc.).

- Evaluating current practices.

- Identifying, prioritizing, and selecting cost reduction areas.

- Testing and implementing improvements.

3. Application with the team - One-on-one coaching to confirm/prepare for initial application. On-site project, with coach as co-lead (real, immediate application and results).

Application and Coaching: 48 hours of on-site event co-lead. One-on-one coaching until results are achieved.

Certification: Participation in this course and completion of 1 project = Continuous Improvement VE/Df(x) Black Belt Certification.