A Getting Ready Story

A Getting Ready story

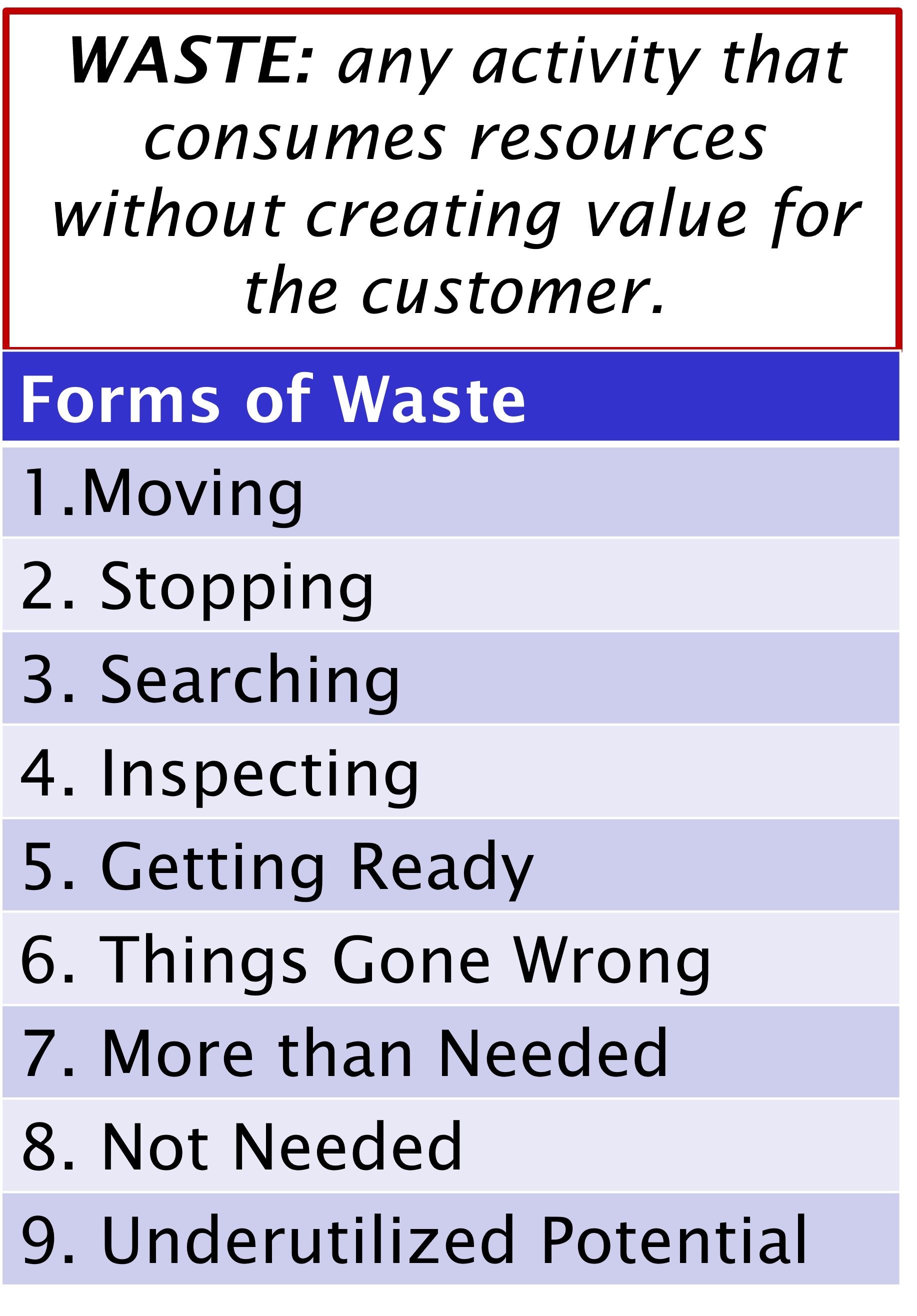

During improvement training, projects, and organization culture transformation, we teach and use value and forms of waste to help see our work lives differently and helps teams achieve performance above and beyond their expectations / beliefs. A recent birthday party highlighted value and waste are everywhere, not just at work.

Successful party planning, (just like project, clinic, production, and inventory) relys on preparation.

Waste #5: Getting Ready is the waste of poor preparation; aka plan and do what can be done prior and streamline all other activites. Rather than frantically rushing around an hour before the party and during the party, getting ready waste and activites were addressed in the days and weeks leading up to the party.

How to remove Getting Ready party waste:

- Prebuild a guest list.

- Create the menu checklist (in order of freshness/spoilage preparation).

- Identify all actions and work the actions over time (with other errands).

- Stage all party areas. Factoring in where guests will eat, play games, and gather to eliminate wastes of #1 moving (trashcans are nearby?), #3 searching (where are the forks?), #4 more than needed (100 plates, really?), and #6 not needed (why is my mail on the counter?). This is so like work planning!

The result

Perhaps you need to ask the guests and birthday girl! Value is from the customers' perspectives.

As the party provider, one hour before the party start time there was nothing left to do! Everything was in its place. We did have one waste, #6 things gone wrong, the speaker sync and volume. There is always room for improvement!

This link is to our value-waste challenge. If you give it a try, let us know your results. Lastly, helping others see waste is a great way to make improvement engaging, meanfully, and fun. Once waste is seen, many want to eliminate it; now you're into improvement.

Take the Waste & Value Challenge

Helping others see and eliminate wastes (Scroll to Continuous Improvement OPPORTUNITIES)

Quick Change (SMED) Training to eliminate process getting ready wastes